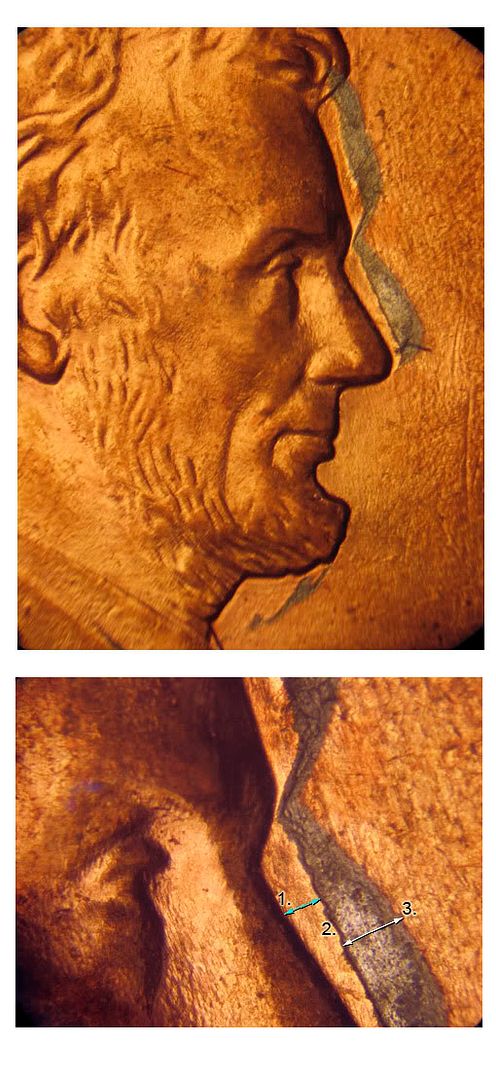

I numbered the illustration with three points (1. 2. & 3.), I did this as it seems these points all were present at the same location at the moment of the initial strike before some of the energy of the strike sent parts of the field away. I think it is safe to presume that points 2 & 3 where connected, I am also thinking that point 1 was as well but I am not 100% certain. I think, from just looking at it (and probably not using the correct terminology), that either the speed or physical distance (or a combination of the two) translates into different results with zinc and the copper plating.

I don't know if the correct term is malleability or ductility (or something else altogether) when describing the differences seen between the copper plating and the zinc in this particular situation. It sure looks like the zinc either stretches out more easily or out further at the speed associated with this strike, then when the energy of the strike is not contained within the collar, the copper plating passes a critical point and snaps at what is now a weak point from where the edge of the die had made contact a fraction of a second earlier.

Another idea I have about points 1 & 2 is that the tear occurs near the edge (but not where the die edge made contact), not because it is weaker, rather, as the bend in the coin makes the copper plating more stable and unmovable and the break rips along a line similar to the profile.

I guess what I am looking to know is if it is a case of copper and zinc exhibiting differences of malleability only or if it has something to do with (in part or in whole) the speed of movement of the two metals during the latter phases of the strike.

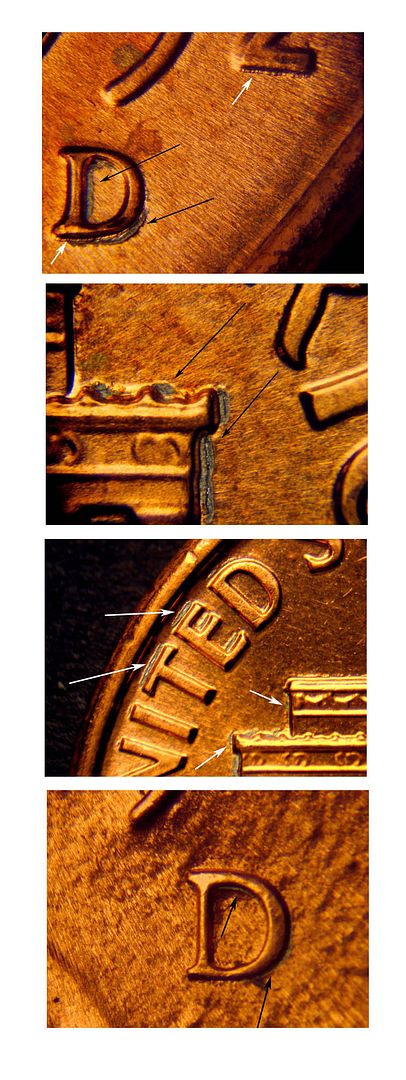

Below the off-center example are pictures of the Plating Split Doubling where it seems to occur most frequently (the mintmark and outer devices on the reverse of the coin).

Comment